Service Center Qualifications

We are ready to take on your service needs. Below are some of the unique qualifications we possess to ensure a quick turnaround with the highest quality possible.

EASA Accreditation

We follow the AR100 electric motor repair industry standard. We have the necessary & required equipment to diagnose & complete a quality repair. Our equipment is calibrated annually. We maintain digital documentation on each repair. We are audited by a 3rd party and have received Accreditation recertification every year since 2015.

WEG Authorized Service Center

Our commitment to quality has also been recognized by WEG Electric. They denoted GIS as

it’s regional Authorized Warranty Evaluation center. Due to our large distribution volume, repair facility & AR100 commitment, we are able to evaluate WEG motors & make warranty determinations all in house.

Documentation & Customer Portal

In the digital age, it is imperative to record any and all information possible on an apparatus we are servicing. Our internal system allows us to digitally record the diagnosis, images, test results, etc. in the hopes for obtaining the highest level quality & for future reference.

- Core Loss Tester (Phenix)

- Automatic Winding Machine (Samatic)

- Dynamic Balancer (Schenk)

- Multiple Overhead Cranes

- Dry Ice Blasting Machine

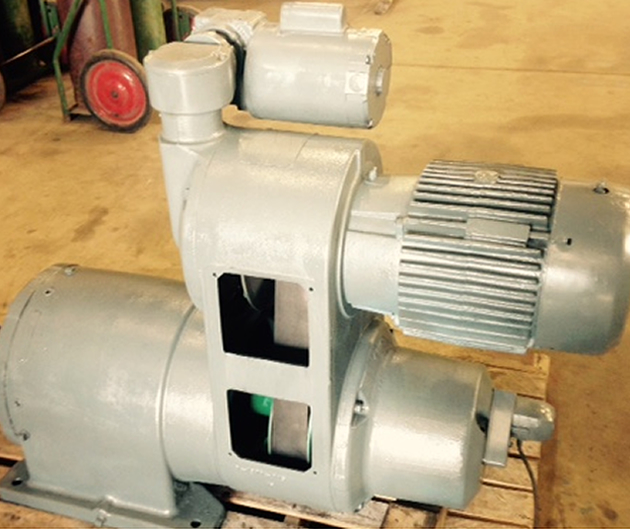

- Only Self Contained Pump & Motor Facility in Region

And the latest addition to our arsenal: Jenkins 500kVA Medium Voltage Test Panel.

Capabilities: Allows for digital recording of Run Test Amp Draw, Vibration, Thermal, and recording of Speed (RPM).

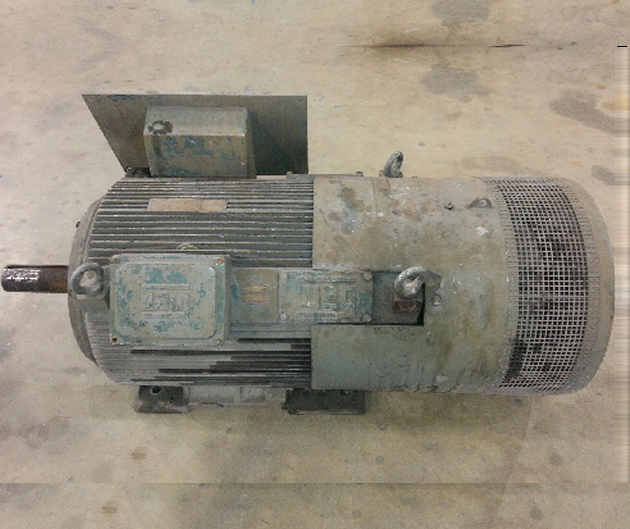

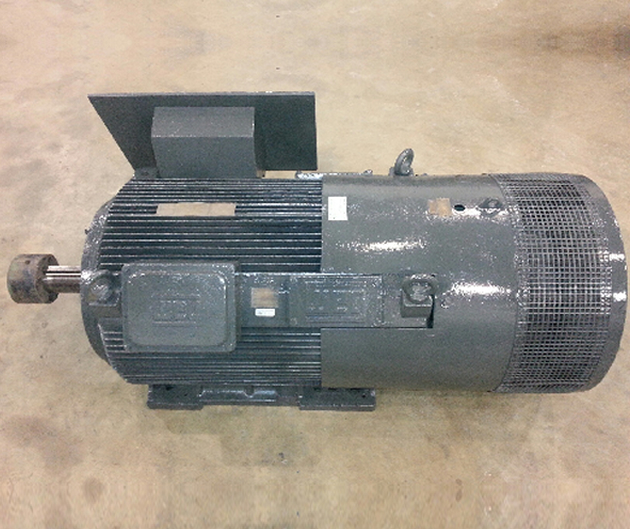

Before & After